DIY

Share your self-made stuff and half-baked projects here.

Also check out !diy@beehaw.org

There is also a related XMPP chat.

Hi,

I would like to build myself a DIY DVR

Here what I'm targeting

-

The software is FLOSS

-

Have a community/free/gratis version that can handle >= 16 cameras and it's usable (meaning not crazy restricted)

or

is paying, but not crazy scheme (like subscription etc..) So you pay once, and you can use that version forever for unlimited number of cameras. -

Lightweight on resources ( can run on a Single-board computer )

-

Can handle Hardware compression.

-

Can handle Passthrough recording (IP camera)

-

Have a HTTP server User interface.

-

Can record audio, when the camera provide it.

-

Motion detection (possible to enable at certain times)

-

extra: Written in Python

-

can record in H265

Thanks.

If you have any reference or any good (recent) article I'm all ears :)

I've actually done a couple posts about softcover books on my movim blog, this one and one previous one. The Fully Automated softcovers are a little fancier, but this one I think is a good example of the benefits of being able to just make a book when you want a physical copy.

I have a few advantages in this project: my SO had already bought a bookbinding kit and book which I was able to use, and I have access to a free color printer, and, through my local makerspace, a plotter printer which can print on canvas. Everything else, the graphic design, the interposing, etc, was done using free tools like GIMP, an online pdf cropping website, and https://momijizukamori.github.io/bookbinder-js/.

It looks like one of the advantages of this hobby is suddenly being able to get physical copies of books that aren't available as anything other than PDF ebooks. I've got a handfull of favorite books from various authors which were extremely self-published, sometimes as serial fiction later edited into a PDF. One or two eventually got a limited print run, or the author made it available on a Print-On-Demand site, but at this point, I think I've found and bought all of those. That leaves a few that I'm very happy to finally be able to hold in my hands while I read them.

Vatsy and Bruno was one of those. Written in 2010 by Adam "Rutskarn" DeCamp, and published on the old version of https://www.chocolatehammer.org/ , Vatsy and Bruno is a high-strung, noire, dark-comedy-adventure story set in a radio-era city under the thumb of vague oppression. It's a fun story, and one that feels like it should be typewritten on paper (preferably cheap, grubby, fish-stained paper with some suspiciously blood-like smears).

Making this one actually took a bit more prep work on the files.

I started with the PDF DeCamp released on his website over a decade ago. This, unfortunately, wasn't really sized or laid out for bookbinding (re. the wide margins, the page size, and all the page numbers being on the right side of the page). I could get really fancy with editing this, but it's just for me, so "good enough done quick" was the order of the day.

I wanted to print this with no extra trimming, so I planned to use 8.5x11 paper folded in half. Unfortunately, the PDF was, itself, scaled for 8.5x11" paper, and when you fold that in half, the aspect ratio changes. So when I fed the PDF into (the tool I use for interposing the pages](https://momijizukamori.github.io/bookbinder-js) it stretched it vertically quite a bit. It was also showing some fairly large margins, which was unfortunate as those came from the original file. So keeping things "good enough" I threw it into an online PDF cropping tool, cropped it closer to what I'd need, and let it stretch the file a little.

I spent a good bit more time on the cover.

The original covers were also the wrong aspect ratio, but they had almost everything I needed.

I used them and a cover from one of the three sections the story was originally released in, to bash this together:

The cover, spine, text, and back cover were all made from DeCamp's own art, just re-arranged to fit this aspect ratio. From there, I followed the same process as before, but with much faster prints (no giant backgrounds) and no trimming the pages (no giant backgrounds) so that part was easy.

Fold, punch, sew, glue:

I took each signature (stack of four pages meant to fold together) and folded each page in half with the bone folder, being careful to make sure I knew which side was 'in'. Then I nested them together.

I made a guide to lay out the six holes in each signature, and used it to punch holes through the fold with the awl. Then I sewed them together following the Penrose Press Pretty Perfect Paperback Guide:

Once the book block was all tied together nice and neat, I clamped it and glued it with three coats of acid-free PVA glue.

My book clamping station certainly looks ragged enough to do the title characters proud.

While it was drying, I swung by the makerspace and printed the cover. I need to remember to oversize these by a few millimeters, because the first one is always a little small. Ah well, maybe I'll find someone with a bookbinder's guillotine someday.

I folded the cover and glued in the book block just like with the previous project.

I find it easiest to attach the cover in three steps, back, spine, front, but I'm sure real bookbinders have better systems. I start with a flat smear of glue down the inside of the back cover, right beside the bound edge and to set the book block down on it. Then I glue the spine with the book upright (this time I tried on top of the bone folder, which has a similar shape). Then I glue the front cover. I squirted some acid-free fabric glue down the spine and used a paperclip to work it further down, to where it hadn't stuck, and then held it in place by hand for a bit to get a closer fit. I like this stuff, it bonds well and it seems to set much faster than the PVA. This time I also used it to glue the bound edge of the front of the book block to the inside of the cover too, so we'll see how that works out.

The results:

Cover size aside, I'm pretty pleased with it. If ever there was a book to glue into its cover the wrong way around, this would be it, but I got that right this time. I'm glad to be able to read it properly, and to finally be able to put it on my shelf.

#DIY #bookbinding

cross-posted from: https://lemmings.world/post/11714128

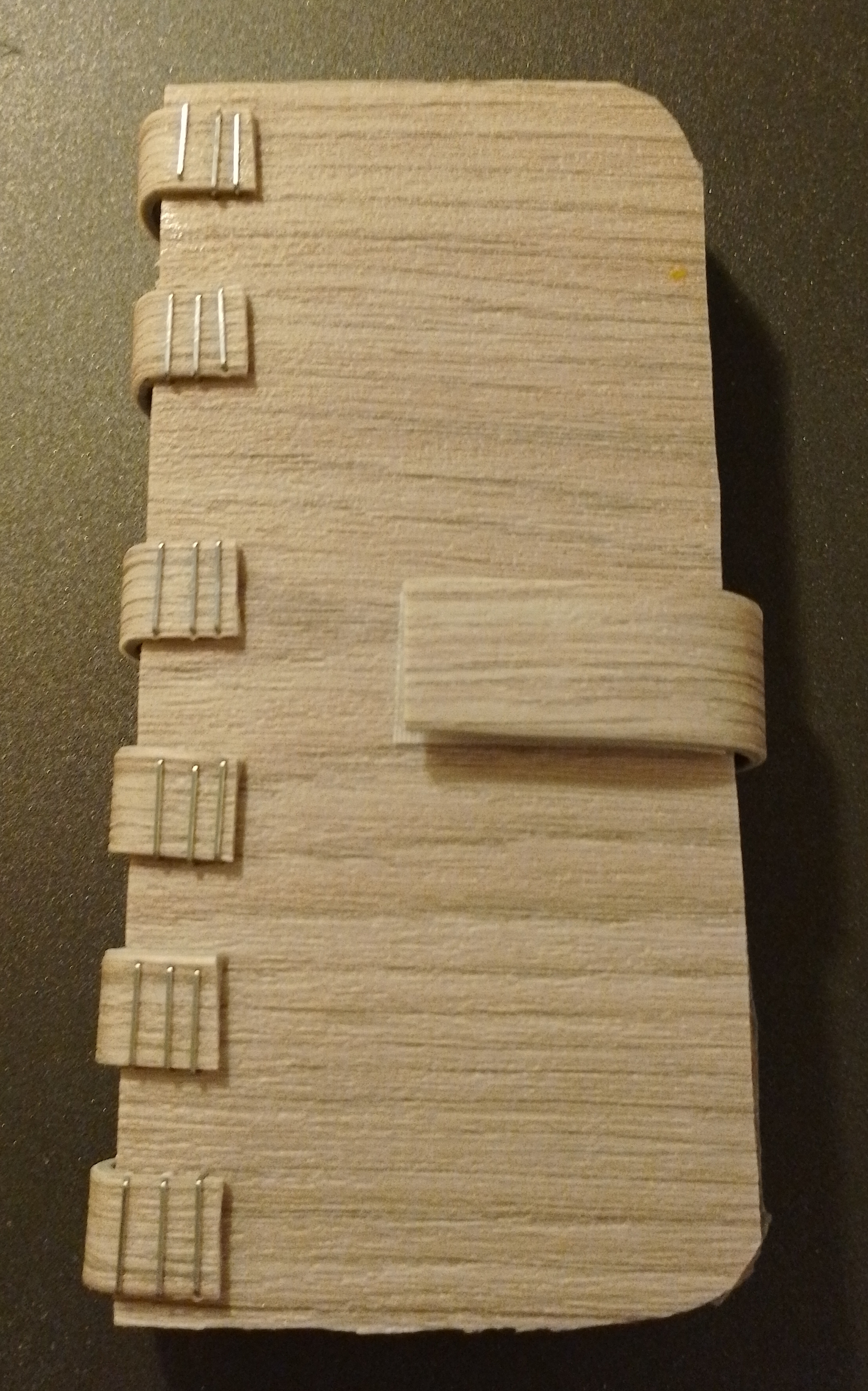

I tried to make a phone "wallet" case. I used the inside of my old one (what you press your phone into), cardboard from a an old box and some leftover vinyl flooring. I originally wanted to glue everything but ended up stapling some bits. these pics where hastily made and don't do the thing justice. Let's see how well this holds up (I seldom have it in my pocket so that helps).

hi all. i live in western Colorado, in the desert part rather than the mountain part, and it's HOT. and sunny. my house has a long west-facing wall full of large windows, and we've been keeping the blinds shut all day but it's not helping. i'm thinking of installing awnings.

my questions are, a) have you done this or something similar, and if so what did you do, b) are there awnings available that are NOT just plastic? and c) any other hints, tips, or ideas would be welcome.

My bathroom tub fixtures have seen better days. Pretty sure they're original to the house (~60 years). We have fairly hard water, and the prior owners were not the best at maintenance so no clue how long these slow leaks have been going on. But the shower handle is stuck hard on the valve, and the bath spigot is crumbling away and similarly fused in place. Hot and cold come off easily.

Does anyone have any tips for freeing the one handle and spigot? I've tried light tapping with a mallet on the back of the handle to no avail. The spigot seems bound pretty tightly, to the point where I'm concerned about damaging the pipe if I apply too much torque.

As for the leaks, I haven't decided if I'm going to just replace the valves, or try fiddling with/replacing the packing nuts. This is my first time messing with plumbing, but either way seems straightforward enough after watching a few videos.

Any tips/tricks/suggestions appreciated, thanks!

I bought this cheap bathroom vanity off of amazon and we assembled it. We cannot get the drawers on. These silver things get in the way. When I get them mounted in a way I feel is correct they prevent the drawer from closing all the way. I haven't dealt with anything like this.

Does anyone know how to mount it? I'm sure once its done Ill feel like an idiot for how simple it is.

Thanks

We have an electric cargo bike that’s served us really well. We bought it second hand at a pretty affordable price because the battery was shot. Fortunately we found a great local repair shop that could replace it, and we now have a pretty great bike.

Unfortunately the drum breaks on the front wheels are getting really bad after about 12 years or so, and our local bike repair shop is at a loss for finding new parts. The front wheels are mounted on an axle that’s controlled by hyudralics (which gives the bike a great turning radius), so they’re a bit special. The original hubs are Sturmey Archer XL-SD’s, but they don’t seem to be available anywhere.

Does anyone have suggestions for what I can use instead? Has anyone hacked their way to one-side-mounted front wheels for a three-wheeled bike, eg by using a through axle?

Hi!

I'm planning to try to get into some solar-powered (or low-powered) DIY projects.

I have a mechanical engineering background so I'm not super worried about learning technical stuff but I live in an apartment and don't really have ready access to a workshop.

Does anyone have good projects they've found? Having some creativity issues more than anything else, I think...

EDIT: I think this video shows a better design, although I note some improvements below:

Making a DIY analog force sensor under quarantine, with the Kontrol Freak. | KontinuumLAB

The main video linked uses two strips of copper bridged by the velostat, but this creates deadzones where those copper strips are, and probably also gives different responses depending on the shape of the region being pressed. I've done more research and a much more consistent method should be to sandwich the velostat between the two conductors so that the entire surface gives a consistent response that goes directly through the material. This should also give a more pronounced response because the length of the circuit through the velostat is only the thickness of the sheet, not the width of the pad. This should also make it less sensitive to changes in the pad size.

Some videos use conductive fabric, but the best one I found uses adhesive copper tape. If you're getting this, make sure to use copper tape that is conductive on the adhesive side, as not all of them are.

And a follow up video with a more refined method of building the pads and ideas about how to improve the analog-to-digital conversion:

Eight pressure-sensitive Velostat/Linqstat pads for a velocity-sensitive MIDI controller

There is also this method using piezo sensors, but from experience I know that this is completely insensitive to sustained holds. It's used for electronic drumkits because it measures percussion, not pressure:

DIY midi controller with 8 Velocity-Sensitive Drum Pads (on one chip Atmega328) 'Very simple'

I suppose combining a piezo sensor with a simple touch-sensitive control might achieve a good effect, but velostat seems like a simpler solution to me. Also if you want a capacitive sensor on the surface you probably can't use the soft rubbery material that nice MIDI pads use.

Also this guy is quite good at his explanations and breaks down quickly how to make a full button pad, although he still uses regular buttons and pressure-sensitive ones would need a bit more logic to understand:

Launchpad || DIY or Buy || Keyboard Matrix & MIDI Tutorial

So I've been looking into how to do this, and I found someone on reddit asking this same question like 3 years ago, and they're still active. I was planning to log in just to link them the video since literally everyone just told them to use regular buttons, but they obviously want to make the real thing, and it's a night and day difference between using velocity sensitive pads and simple buttons. Also they said they live in India where a lot of musicians can't afford the more intuitive interfaces because they're massively marked up, and I thought they should have the information they need to make a DIY solution.

Anyway, I realised giving them that link would be contributing to making reddit the go-to place for information, but I didn't find this there, I don't spend time there, and in fact my alts keep getting banned, and I'm the one adding the information.

So since reddit doesn't want me, I figure the best way to solve this is to make a post here and link them to it. That way I'm helping them with their problem, adding content to the fediverse, and linking people here.

The only thing to add is that I plan to expand on this to make a proper MIDI controller using some of the second video's suggestions for improvements, and I'll be making a modular set of boxes that can magnetise together to arrange however we want. Also I'm going to look for translucent silicone rubber that I can illuminate with RGB LEDs so the sequencing can be animated.

Anyway, if that person or anyone else finds their way here, hello! Welcome, this is a much better place than reddit.

So I have this silly idea/longterm project of wanting to run a server on renewables on my farm. And I would like to reuse the heat generated by the server, for example to heat a grow room, or simply my house. How much heat does a server produce, and where would you consider it best applied? Has anyone built such a thing?

Something neat I've discovered - you can repost the content of your movim blog straight into a lemmy post and it's all compatible, uses the same markup. I'll repost all this to imgur as a backup at some point but for now this is awesome.

This was an earlier project on my make-everything-from-junk adventure. I've actually built two arcade cabinets - the first with the goal of using only secondhand stuff, sort of sequestering various junk into something that would be around for awhile, and eventually gave it away on our local Buy Nothing -type group. It was unfortunately very poorly documented, I don't have many pictures of it.

This second one was a gift/reason to hang around in the workshop building something with a friend. They'd seen the first one, and we got talking about building an arcade cabinet custom for them. I like projects that cross a few domains, woodworking, painting, electrical, etc, and I really like reusing materials. Ad I love having a reason to hang around working on projects with friends, so I was excited.

I really like the archival efforts around old arcade cabs, but I generally think of new custom-built arcade cabinets as being kinda wasteful. They use lots of new material, particle board, etc, and take up lots of space, often for a luxury item that doesn't end up getting used very much.

But playing retro games was actually already a big part of this friend's mental health routine so I knew they'd use it - and I was confident I could find most if not all the material secondhand, which would save them a lot of money. (In the end, we did use one panel of storebought particleboard for the front plate/door just to get it finished. Otherwise, aside from the buttons and raspberry pi, we still managed to make it all from old stuff.)

I started with what we already had: various 2"x4" and 1"x2" boards, some particleboard and plywood cut to the dimensions of the previous cabinet which could work as shelves, and most of the particleboard from a big upright storage cabinet which would be perfect for the sides.

A year or two earlier, I'd spotted it disassembled on trash day on my way to work. I hate to pass up good material so I quickly hauled it home before getting back into my routine. When a different friend really wanted to carve pumpkins during the COVID times, I took the sides of the cabinet, screwed on four table legs I got from metal recycling and set it up as a long table on our porch.

We used that table for quite awhile, as a simple workbench, and a side table at friendsgiving.

The pieces I'd used as a tabletop were just about perfect, a good height and depth, if you stood them on end. Unfortunately some fool had driven a bunch of screws into them, but that's what bondo is for.

Maybe it seems counterintuitive to start with materials rather than a design, but that's a big part of how I've always made things. I take an inventory of what I have, figure out how it can go together, figure out what kind of designs we can make with that, and work out a list of what else we'll need. I should note we also already had a TV - it belonged to my friend and it was important to them that we use it since it had no input lag (apparently the TV I got secondhand for the previous cabinet did, and that was a problem). So we knew the measurements there and it was compatible with what we had. Maybe it's just where I am, but I've found TVs of an appropriate size for an arcade cab screen to be absurdly easy to get, either from Buy Nothing or my local swap shop.

We now knew the upper limit on the height of the cabinet (as set by the cabinet/table pieces) and the width we'd probably use (based on the shelf pieces). Those were our constraints, so we started talking requirements. My friend is very tall, tall enough that on my more traditionally-shaped arcade cab, the marquee/roof blocks their view and they had to hunch forward to see the screen. The control panel was too low, making the posture problems worse. This would have to be taller in order for it to be comfortable. They wanted to be able to use it at parties, so the screen couldn't be recessed too far into the cabinet (either we'd have to cut the sides away like a traditional arcade cabinet (difficult to get that just right, likely we'd mess up the plastic cladding on the particleboard) or it'd have to be close to the front. They also wanted it to be sturdy. Really sturdy. I really enjoy overengineering things, so I was looking forward to that part.

My first suggestion was that we do something based on this Gravitar 'cabaret' cabinet prototype.

I had a few reasons for this: the marquee was below the screen, so the screen and controls could be as high as possible. The screen was closer to the front, so it would be easy for spectators or groups of players to see it from an angle, and the overall adjustments to our side panels would be aggressively simple. Two straight line cuts at a matching angle, that I could do.

We talked design ideas a bit, as now was the time. We could do a specific game, or something generic (although I've always found the mame and other generic all-videogames themes to be really uninteresting, personally). Perhaps because we were basing our design on an abandoned prototype, they decided to aim for "like we found some weird pirate arcade machine out of time" and they picked the theme 'goblin dive bar' based on our shared love of warhammer.

I started drawing up a cabinet design, we talked about a logo and I made this from an old warhammer orks and goblins design:

Many thanks to them for pushing me to make it simpler and simpler. I think that was a good call.

Arcade cabs are a great project because they take at least a little of everything - I really enjoyed the graphic design bit and went on to make stickers to cover it with later. With that figured out, I added a couple other flourishes, the moons on the marquee plate and the yellow buttons. My friend picked the name of the arcade company and we tried some stencil fonts and a layout for the side art.

This is the mockup I gave them. It's pretty hacked together but I wanted to make sure we were working from the same plan.

Once that was done, it was time to start building. My original plan called for a frame of 2x4s forming a cube inside the structure, with 45 braces at every corner, with the sides attached like cladding. In the end that was mostly what we did, but we used some smaller boards for the frame and relied on the sides a little more for the structure.

I tried to find my original sketches, but wasn't able to. Either they were on wood I've since used in another project, or they're on some envelope or receipt mixed in with the rest of my detritus. Instead I drew this up from memory and the pictures I have:

This sketch shows all the framing without the sides, front, or control panel. All of this was scrap lumber. The uprights were mostly a 6"x4" pressure treated post we ripped lengthwise on my neighbor's tablesaw (wear a dust mask if you're going to do that), the supports for the TV were scraps of house siding, and the big board supporting the TV was I think a scrap of 2"x12" which had been used as a concrete form and was pretty much garbage as far as materials go even after I scraped off most of the concrete.

We wanted it sturdy, so it had to have an internal frame so it wasn't relying on the particleboard sides for structure. I wanted the control panel in particular to bear its weight through the frame right to the floor. We also screwed everything to the inside of the sides of course, and that on its own was surprisingly sturdy. Lots of 45 degree braces helped to ensure it wouldn't sway or twist at all.

The TV frame was an improvement over my last design. On that one, the flatscreen sort of just rested in place on some rails. This time I wanted it to be fastened in place - after all, we were going to have to move this to my friend's place, and then they'd be moving it from apartment to apartment (and they since have, with no problems!).

I don't have a ton of pictures from early on (I never think to take any until it starts to look like something). Here's one from while we were trying to make that 2"x"12" look better with bondo. Even once it was sanded smooth it still looked bad enough painted that I eventually cut a piece of plywood as cladding to cover it.

We made the control panel from a piece of 1"x14" composite pine I got from a disassembled ikea bookshelf I found on trash day. When I was working on the last arcade cab, I asked around on our Buy Nothing page and met a professional woodworker who had a large table router (this is before I got my little one). He helped me rout a round edge onto my control panel (plus a spare in case I messed up drilling the holes for the buttons) and to cut a slot I used for the marquee.

My friend and I used my spare to make their control panel. They picked the layout using some more lessons learned to improve on my first one, opted for the same sega layout I picked (found here) and we drilled the holes. They opted for a nicer set of authentic mechanical buttons and joysticks than the cheap kit I'd used the first time around, and I think that was a great call. Those buttons are also useful in other electronics projects.

We also filled in the front cut edge of the particleboard sides with bondo and sanded it smooth.

Once we had the basic structure and made sure the TV could fit, it was time to paint it (while the weather was good).

For this I printed out a large stencil at the local makerspace and cut it out by hand.

This was a large but simple four-layer stencil (black circle, yellow, red, white) so cutting it out took no time at all. Unfortunately, the only paper available for the plotter printer was super flimsy, and that would be a pain later on.

For the first paint session we only did the round logo. We weren't sure we'd be able to do both sides, so we started with the one which would face the room (this side also got the best particleboard). We had a bad combination of elements here - flimsy paper and because I couldn't find my good artist's yellow spray paint, we were stuck with some generic watery hardware-store-brand spray paint with the approximate thickness of kool-aid. We had to paint the black circle, paint the stencil of the moon with white, then use the yellow over that. By then the stencil had warped and in some places stuck, so the black layer was messed up with underspray and missing paint. Luckily we still had the 'negative' from the stencil, so I used that to protect the yellow while I fixed the black. Then we did the white and red.

All of that was a mess and I wouldn't recommend it as a strategy. It was one of the worst ways I've had a stencil project go, but the end result wasn't bad.

And in a second lucky break, because it was sprayed onto particleboard, it actually cleaned up pretty well with isopropyl alcohol.

The finishing touch for that side, the company name, was comparatively easy. dimensionally it just fit inside the laser cutter, so we used that to cut it out of cardstock.

I think we even painted this one on indoors (another bad idea but the cab was heavy).

We definitely weren't going to repeat all that for the side facing a corner, so we did a simple two-color racing stripe instead.

It's always nice when your stencil is just a length of painter's tape and some newspaper. Even that garbage yellow paint couldn't go too badly this time around.

We made another trip to the makerspace and cut out a couple more things. The first was the very basic phases of the moon template I'd bashed together for the front marquee, the second was a fake coin door and buttons I found online.

We thought about doing something fancy like getting a real coin door, wiring up buttons so you had to push them for the 'coin' button in the emulator, but it seemed like a wiring hassle and our plan was for the lower part of the cabinet to be storage, so it'd be better if there wasn't wiring hanging around in there.

Painting the stencil on wasn't hard because we didn't have to haul the whole cabinet outside, we just painted a thin strip of particleboard with veneer black and stenciled it, then attached it to the front above where the door would go.

Now it was time for wiring. We got the TV in place and fabbed and test fit its bezel. (The bezel was too big for the laser cutter so we had to cut it by hand with a box cutter and a straight edge.)

I marked the mounting holes for the screws in the back of the TV by putting in some screws, daubing black paint on the heads, and settling the TV in place against the back board. That got close enough, though it was always a pain screwing the screws in through crooked holes in a pine board. I don't think we usually had all four attached, but it didn't seem to make much difference, the weight was on the board underneath, the screws were just to keep it from falling out when it was moved.

Then we added the buttons. Suddenly it was starting to look like something. I had to keep shooing my friend off the control panel (which wasn't currently doing anything) because they were so excited about trying out the joysticks and buttons. The verdict was good though, it was a comfortable height for them, even with shoes on. No carpel tunnel risk on this one.

Oh yeah, cable management is my passion. I think my friend eventually redid it so they looked nice.

I wired the cab up for power using some outlets and a lightswitch I got from our Buy Nothing Group, some spare wire, and a power I cord I ripped off a refrigerator someone was throwing out. (Don't worry, they'd already taken the doors off and dumped it in a pile face down on the curb). Learning from last time, I set it up so two sockets were switched and two were on all the time (so the TV could be left on). It's a fairly simple circuit, but just in case I took a ton of pictures and ran it past an electrician I know, who said it looked fine, asked if it worked, asked if it caught fire, and gave me their blessing.

I printed the case for my friend's raspberry pi. I know we could have used a regular old junk PC and still even been able to run retropie if we wanted, but they were planning to leave it running most of the time, and the pi has comparatively low power requirements, so that seemed like a good long-term plan.

It lives!

You might have noticed that somewhere in here the design had changed. My friend was worried the 'shelf' area for your hands on the original design would be too crowded, and the screen was a bit close. Considering that it was a widescreen TV which would only be showing a square game in the center, the cabinet sides didn't actually hide much. And standing the TV here simplified construction even further.

I cut a separate marquee piece for the bottom of the TV (I think because the design changed somewhere along the line?). It had a cutout at one end so the TV could see the IR light on the remote, and so the user could reach the buttons under the screen.

I glued the two pieces together, painted them, and worked out a way to attach it using hangers at the top. I remember it being difficult to attach it in a removable fashion, without anything showing on the front, and this is what I came up with.

The final design used wooden pegs to fasten it together for some reason, and I remember you could push them back out using a pencil which was handy during all the test fitting. There was probably a better way but this has held up fine.

The next step was finding enough flat, single panel material for the front panel/cabinet door. I watched our Buy Nothing and Everything is Free groups, and scouted around on trash days for months, looking for something big and flat enough (tabletops etc) and had no luck. A few house doors came up but they were like an inch too thick for how we wanted to do the hinges. Finally I gave up and bought a slab of particleboard. The home depot I got it from was able to use their fancy saw to cut straighter edges than I could have with my skillsaw, which was great. When he was done, the guy asked if I wanted the rest. I said they could keep it to resell, I was happy to pay for the whole thing to get the piece I needed, and he said they'd just throw it away. That's how I ended up with a (I think) four-foot by eight-foot piece of particleboard cut into two door panels and one long piece. The spare door eventually became the top of this table. The long piece hasn't found a use yet but it'll probably end up being a shelf. I haven't gone back to those stores since.

The last piece was a bit of cladding glued/screwed to the board under the TV. I honestly cannot remember why I did it this way, but I painted it black, glued it in place, and we only decided after to add labels to the buttons on that piece.

I took a bunch of measurements of the buttons, lasercut a couple very simple START SELECT stencils with various spacings, found one that fit well, stuck it in place (probably with easy-tac), masked the area with tape and newspaper, and gave it a couple quick hits with rusto white.

Considering the circumstances, I'm pleased with how they came out.

The last big task was moving the thing. That was a challenge as making it sturdy made it pretty heavy, though not as heavy as the real thing with the big CRTs would have been. We rented a moving truck, and used ratchet straps to fasten it to the back inside wall, standing upright, wrapped in blankets. As a bonus, we also delivered some speakers my neighbor wanted to give away.

My friend was planning to replace an armchair in their apartment with this cab. Their plan was just to throw it away, but first thing when we got to their apartment, I posted the chair to our local Buy Nothing page with the promise we'd deliver it. Then we set about hauling the cabinet inside, rearranging furniture, getting everything hooked up, cleaning off months of sawdust, and finally testing it out.

Hanging out, finally playing games on the arcade cab, in the place where it was supposed to be, was awesome. It's since seen a lot of use at parties, and it gets a lot of attention from newcomers to their apartment. We still haven't gotten around to stickerbombing it yet.

By the time we were done and the celebratory snacks had been eaten, we had a taker on the chair. We drove it to their apartment and carried it upstairs on the way back to the rental place.

One of my hobbies is fixing up ewaste laptops and giving them away. I actually do lots of ewaste electronics, from TVs to space heaters, but the laptops are where I put in the most work. Some are new, intact, and ready to go with nothing more than a OS reset. Others have had parts removed or damaged, and need more work. Most of these computers I give to a local refugee resettlement organization, but some of them are old enough, or otherwise weird enough that I wouldn’t feel right about giving it to someone who already has a lot of problems to deal with. I try to make sure they get fast computers with familiar operating systems whenever possible. So far, I’ve always had enough decent machines to pass along that that hasn’t been an issue.

Through this project I made friends with a guy who works at the local recycling center. He does a similar thing with TVs, though covering even more organizations and moving more equipment than I do. He helped me up my game a lot. He provided some old Windows multi use keys, a ton of cables and USB hubs to give away with each laptop, an almost endless stream of power bricks for any model I needed, and recently he was able to get the management there to agree that he could take laptops too, if he caught the people who dropped them off and asked if they were okay with it. Otherwise the site policy says they need to be securely destroyed.

So suddenly I had two sources of hardware, which was a huge help in providing computers to everyone who needs one. Not all of them are great though – sometimes you get a laptop with a single DDR1 ram slot (can’t go above 1GB), or in this case, a couple chromebooks with expired, insecure OSs. He wasn’t sure I’d be able to do anything with them, and asked me a few times if I was sure I wanted them, but I didn’t feel it was a big risk. I’d try fixing them up and if there was an issue, I could always put them back in recycling. Neither one seemed like a great fit for the refugees, they only had 2 gigs of RAM and 16 gigs of on-board storage space. No hard drives. But the hardware was nice, lightweight, with a nice screen and keyboard, and the batteries were awesome. I hate to throw something like that away.

I started with reading about my options and settled on MrChromeBox’s script for replacing the ChromeOS and firmware with a proper BIOS. The website and instructions were thorough and worked perfectly for me.

Step 1 was removing the hardware write protection. All chrombooks have some kind of write protection that prevents you from paving over their firmware. In some it’s a jumper wire connecting two contacts. On others its a lack of a jumper. Sometimes they use a screw to bridge those contacts, and on some, the battery itself acts as the bridge and you can only reinstall the BIOS when the battery has been disconnected and the laptop is plugged in.

Mine was an easy one, enabled with a screw. The website didn’t have a photo for this model, but it wasn’t hard to find since it looked different than all the rest. (I’ve since sent this photo to MrChromeBox in case he’d like to use it.) Once that was out of the way, I followed their instructions to get to the correct command line interface and entered the commands to run their script. Very satisfying. A great ratio of ‘feeling like a hacker’ to actual effort involved.

Once the script completed, I had basically a regular laptop. Probably closer to an old netbook in terms of hardware. I could install Linux Mint but it would take up most of the storage space. I received a bunch of microSD cards as a gift, so I bought a super low profile microSD to SD adapter and stuffed a 512GB microSD into the SD slot. That’s going to be a pain to get out some day.

The BIOS is happy to boot to the SD slot, so I installed Linux Mint there. Suddenly I had a regular laptop with plenty of storage space, a bit light on RAM, but it’s a perfect little computer for carrying around the city and going to write-ins, etc. Light weight, good keyboard and touchpad, awesome battery.

I know I could have used a lighter weight OS, but Mint is sort of my default, its super convenient, has wonderful compatibility, good community support, and just works well when I want a computer that isn’t itself, a project. Between the web browsers, the preinstalled Libre Office, and the writing tool Wavemaker Cards, I have everything I need for most of my projects.

A few days into using it we had a makerspace night, and since I had access to the laser cutter, I put together a quick solarpunk stencil. I love using the laser cutter to cut stencils. It turns hours of work into minutes, and it can do intricate designs with narrow bridges that I’d often have to glue back together after tearing or accidentally cutting. Plus, it works best when cutting thick cardstock paper or thin cardboard, which makes for better stencils, but is a pain to cut by hand. To reduce waste, I used an old cracker box for my stencil.

Once it was cut out I saved the bits and pieces in case I wanted to do this design as a reverse stencil sometime.

To make sure the size was good I laid out the bits and pieces on the center of the laptop. Eventually I corrected the tilt so it followed a line from the top right to the bottom left corners. Once I had it in the right place, I lightly taped the gear part in place so I could use it to position the actual stencil later on.

With this one there wasn’t any reason not to use some temporary spray adhesive, so I spritzed the cardstock with that, let it dry enough not to leave residue, stuck it down, and peeled up the gear. I usually use old return address stickers, the kind charities send you forever after you donate once, to cover up any gaps on the stencil, and to keep the other masking stuff in place. The stickers are great whenever you need tape but don’t care how it looks.

I used the same yellow graff paint I had from years ago and recently used on another project. I tried to hit it straight down, mostly to avoid anything slipping in under the edge of the stencil and because I hadn’t masked the rest too well. With such a simple stencil it wasn’t really a big deal. Once it was done I had my traditional moment of panic as I realized I hadn’t really checked that I’d applied the whole thing right-side-up, but it worked out this time, saving me a lot of hassle. As paranoid as I am about other measure-twice-cut-once preparation tasks, you’d think I’d be better at this one.

And that’s about it. The laptop’s working well, I’m actually writing this post up on it at the moment. Overall it’s a good little writing laptop, and I’ll probably set its sibling up the same way soon enough.

There are several DiY communities in the fedi but if we ignore the big centralized instances, there is:

Perhaps each would consider mentioning the other sister community in the sidebar?

This type of battery seems quite easy to DIY. Cheap materials, relatively safe, not flammable.

You can either maken individual cells or make a flow battery which is theoretically infinitely scalable. You'd be limited by the size of the electrode in how much power this battery can deliver.

Has anyone here tried to make a flow battery? And did you have any success with powering something large and energy consuming?

I guess it would also be possible to make a battery out of old buckets, carbon fiber mesh and separator material such as glass fiber.

Hi all

I have an electric kettle I use to boil water often. I bought is because it is stainless steel, except for the indicator to see the water level. Of course this plastic part is now leaking...

Does anyone have an idea how to fix it? My idea would be to fill it with silicone, but not sure if that is safe for use with foods

Seems interesting as a YT alternative for show-casing DIY projects.

I love this person and everything they do.

Here's his take on the latest project, in this video:

This year I attended an art workshop on publishing and print-making. The goal was to make an art book, with total freedom of form and design. Here is "unrolling", my take on the (broad) concept of a book, with scrolls, spools and rolls.