3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

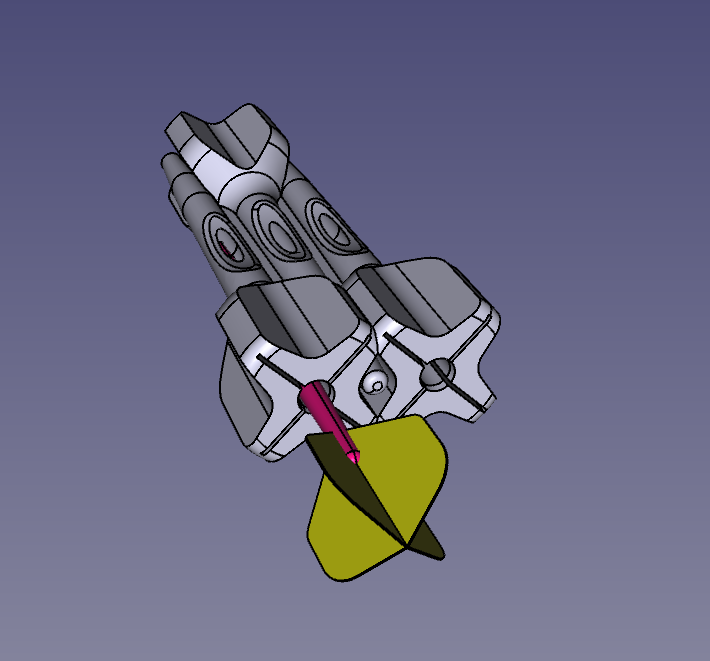

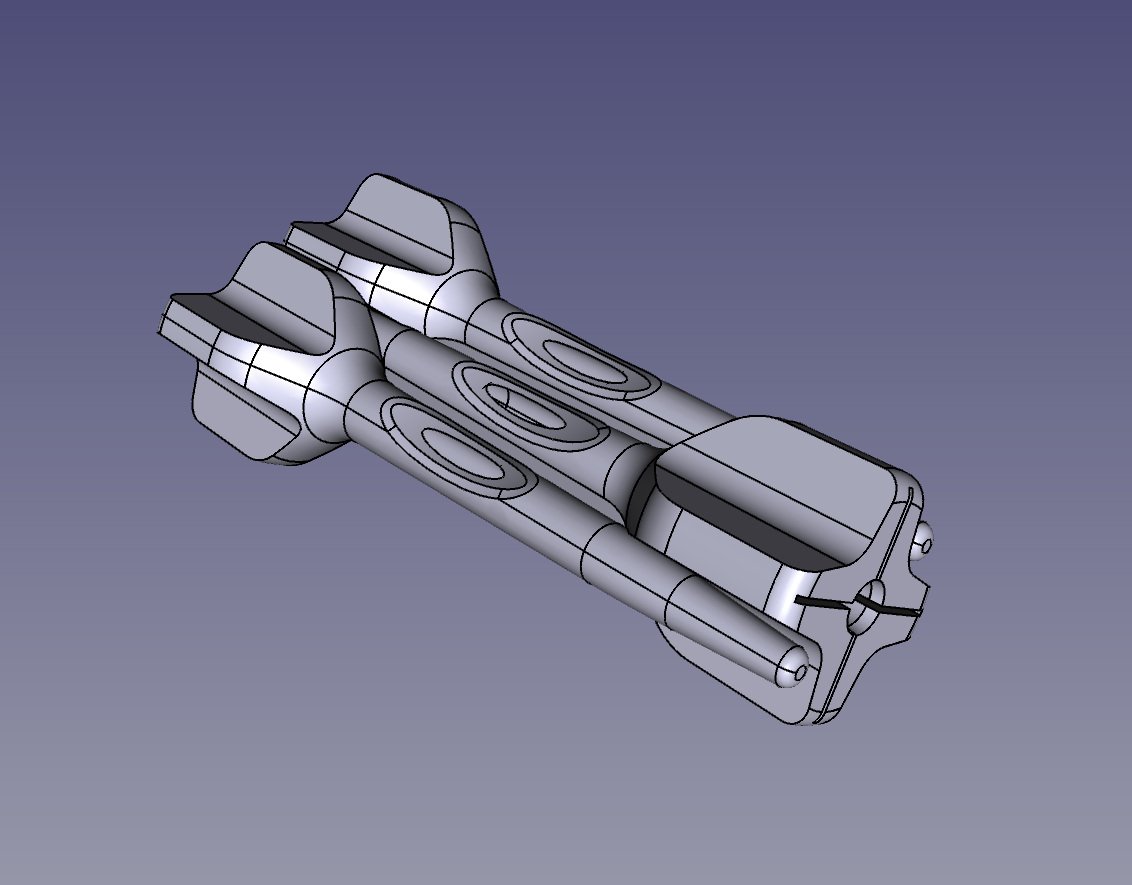

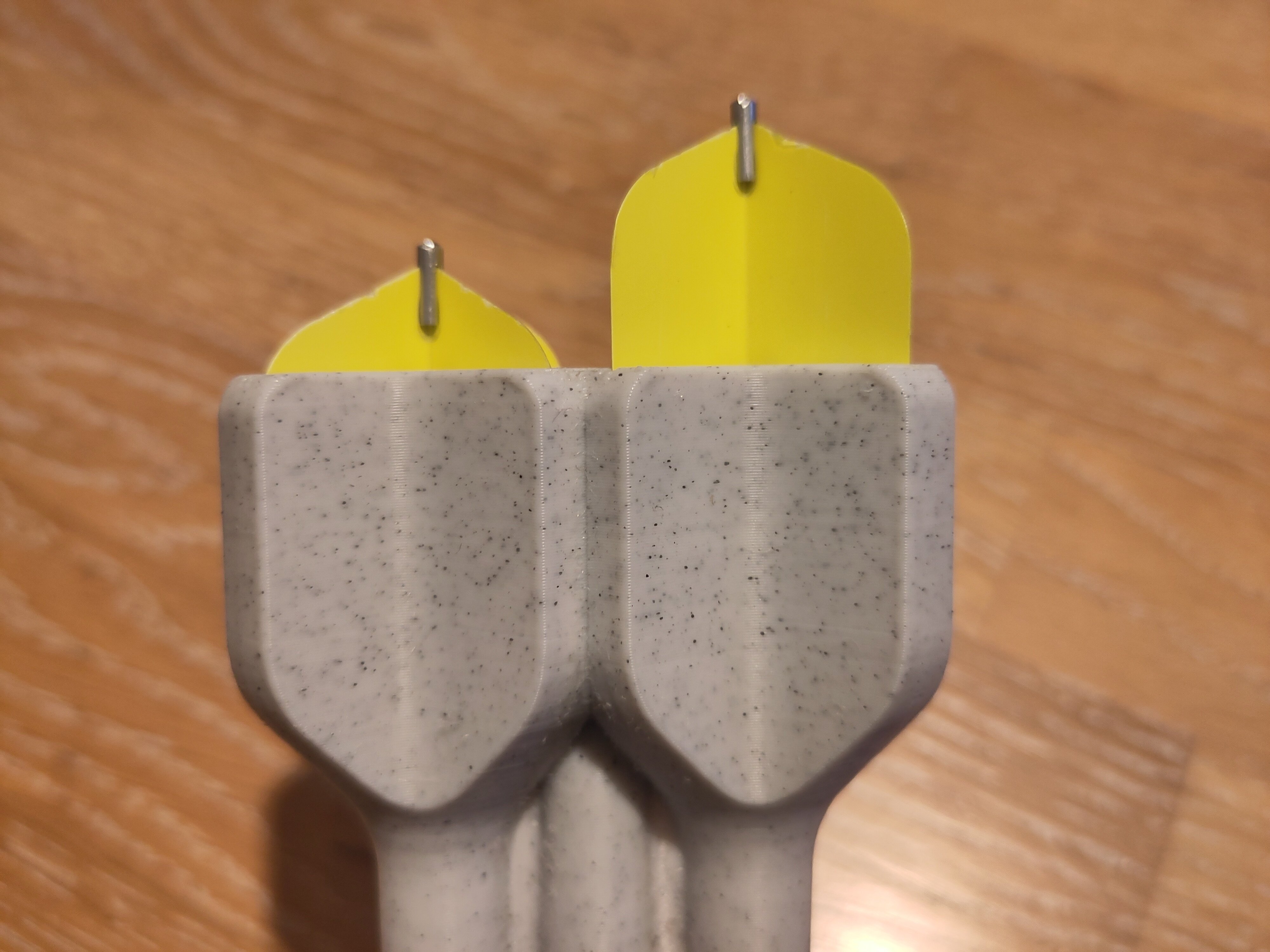

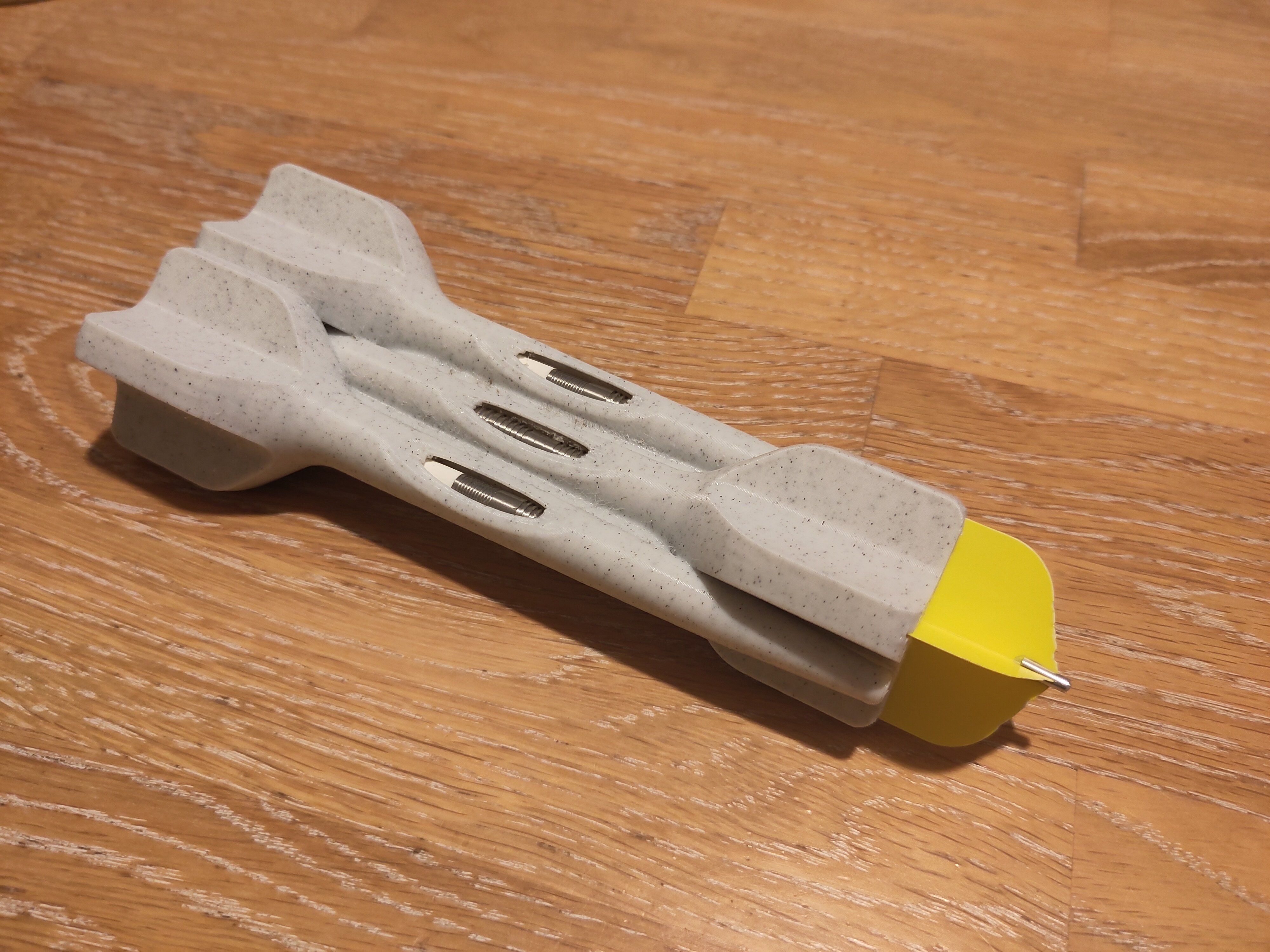

If you ever printed a 2nd iteration, you could created a space for an oring to sit for each dart so it gets lightly held in place by friction

I was going to say to just make the end slightly undersized so when you push it all the way in, it gets held in by friction.

Giggity.

It's a good idea but I'm sceptical about anything friction to hold the darts. The problem is that they have very sharp machined rings that make them very non-slippery to the fingers. I'm pretty sure those rings would file off anything they slide against very quickly.

The steel tip does not have this problem though, so adding some part that pushes against the tip might be the solution. Alternatively, i could also make the part that houses the flights be somehow spring loaded and squeeze them.